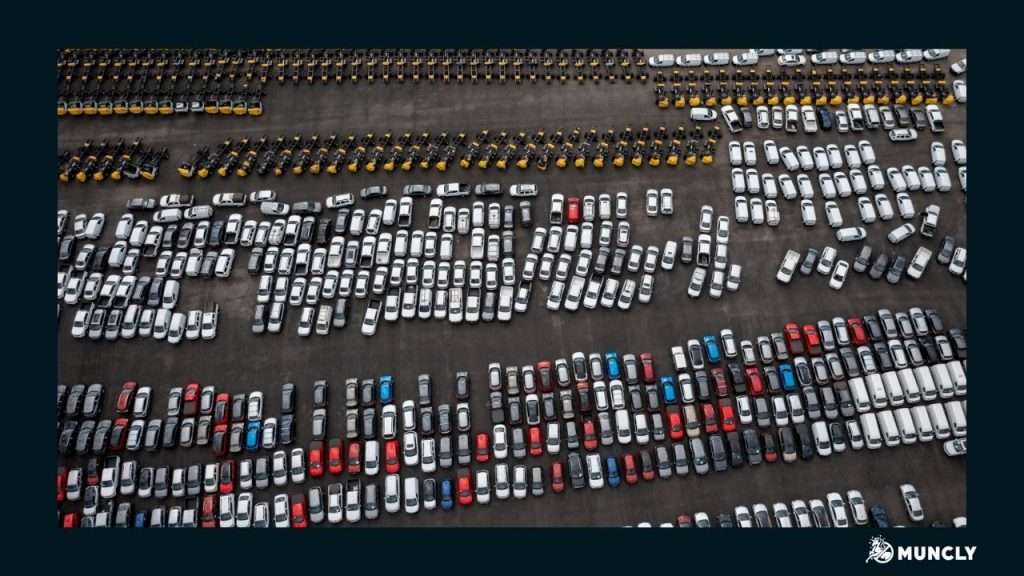

The automobile industry, with its vast automotive supply chains and myriad of components, stands as a colossal testament to the importance of effective inventory management. In the supply and demand balance, gears align for smooth operations.

This article aims to provide an educational perspective on Automotive Inventory Management, shedding light on its pivotal role and nuances.

Understanding the Basics of Inventory Management Systems

At its core, Automotive Inventory Management is the systematized approach to sourcing, storing, and selling inventory—both raw materials (parts) and finished products (vehicles). This strategy ensures that businesses maintain optimal stock levels, reducing costs while ensuring product availability.

Addressing its importance, this methodology stands as the backbone of the automotive industry. An efficient inventory system translates to streamlined operations, reduced holding costs, improved cash flow, and, ultimately, heightened profitability.

Efficient vehicle inventory management system is paramount to profitability. It optimizes storage costs, prevents over-purchasing, and ensures timely availability of products.

In a dynamic industry like automotive, where models evolve and consumer preferences shift, vehicle inventory management system remains the cornerstone, driving profitability and customer satisfaction.

The Four Pillars of Inventory Management System: The 4 Types Explained

Just-In-Time Management (JIT)

Emerging from the heart of Japan’s manufacturing prowess, JIT emphasizes reducing in-process inventory and the carrying costs associated with it.

Rather than maintaining large stockpiles of components or finished products, JIT relies on timely production and delivery.

In the automotive industry, Toyota stands as a shining beacon of JIT’s effectiveness. The company implemented this approach, not just as a method, but as a philosophy, aligning every aspect of its production to this principle.

This cut waste and boosted efficiency, to follow more agile path.

Materials Requirement Planning (MRP)

In the vast and interconnected world of automotive manufacturing, coordinating multiple parts and processes requires a meticulous and sophisticated system.

Introducing MRP, the computerized manufacturing optimization system.

MRP works by determining the right quantity and timing for the production of items. It takes into account several variables like lead times, stock levels, lost sales and sales forecasts.

Major automakers, such as Ford, integrate MRP systems into their operations. This assists in streamlining production schedules, ensuring that manufacturing aligns perfectly with actual sales figures and future demand projections.

Economic Order Quantity (EOQ)

Inventory management, at its core, is a balance between having sufficient stock to meet demand and minimizing the price associated with holding this stock.

EOQ is a mathematical model that helps companies strike this balance. By determining the ideal order quantity and order status, businesses can ensure that they order just enough to satisfy demand while minimizing storage price and potential stock out risks.

In the context of the automotive industry, it is a great dealership inventory management. When it comes to ordering vehicles or equipment, EOQ prevents costly overstocking or understocking.

Day Sales of Inventory (DSI)

In a fast-paced industry like automotive, timing is everything. DSI is the metric measuring inventory-to-sales turnaround time. This metric is crucial because it provides insights into operational efficiency and cash flow.

A lower DSI indicates faster stock turnover, implying efficient operations, while a higher DSI might point to overstocking or reduced demand.

For automakers and many dealerships, continuously monitoring and optimizing DSI can lead to better financial health and more synchronized operations with market demands.

Applicability to the Automobile Industry

JIT:

It was once the domain of a few innovative companies, and has now been embraced by automakers globally. Toyota’s success story serves as a testament, inspiring companies worldwide.

By leveraging JIT, they reduce waste, streamline operations, and adapt quickly to market shifts.

MRP Systems:

With their ability to sync various aspects of production, MRP Systems have become indispensable. Automakers, even giants like Ford, depend on these systems for synchronized production and market-driven efficiency.

EOQ:

Its importance in the automotive world cannot be understated. Dealership, confronted with the dual challenge of space constraints and the need to meet rapid demand changes, utilize EOQ models to make informed decisions on inventory.

DSI:

DSI is all about speed and efficiency. Whether it’s an up-and-coming electric vehicle manufacturer or a legacy brand with global operations, DSI provides invaluable insights into how swiftly products move from the warehouse to the consumer, helping businesses stay agile and responsive.

Tackling Auto Parts Management

Managing auto parts poses unique challenges. Given the variety and specificity of equipment, tracking becomes complex. There’s also the hurdle of obsolescence as models get updated.

Leveraging technology, adopting RFID tagging for parts, and ensuring regular audits can offer solutions, minimizing discrepancies and wastages.

Learning from the Manufacturers

Manufacturers often stand at the vanguard of inventory management innovations. Their scale and complexity demand it.

For instance, many have adopted AI and machine learning for predictive analytics, giving insights into future demand patterns. Others make use of the latest inventory management software for improved supply chain efficiency and streamlined operations.

These techniques offer invaluable lessons for dealerships and suppliers, highlighting the importance of adaptive forecasting and proactive management.

Golden Rules of Automotive Inventory Management

- Rule 1: Keep It Lean: Avoid the pitfalls of overstocking. Embrace the JIT ethos, ensuring inventory is available when needed, not languishing on shelves.

- Rule 2: Embrace Technology: From AI to RFID tagging, technology can radically optimize inventory management. Invest in up-to-date systems and inventory management software that offer real-time insights and predictive capabilities.

- Rule 3: Regular Audits and Checks: Routine checks are non-negotiable. They help in identifying discrepancies, potential theft, or wastage, ensuring the system’s integrity.

- Rule 4: Foster Strong Supplier Relationships: Build trust and understanding with suppliers. A symbiotic relationship ensures timely deliveries, quality assurance, and potentially better credit terms.

- Rule 5: Continuous Training and Upgradation: The world evolves. Ensure your team remains updated with the latest in inventory management system practices through regular training and skill upgrades.

The Role of Sales Team and Service Team

Sales team and service team are the pulse of a dealership. Their feedback is crucial for inventory decisions. These teams, being at the frontline, can offer insights into customer preferences, potential demand spikes, or customer issues with existing stock

Recognizing their pivotal role and challenges faced by them, and integrating their feedback into the proper inventory management process, can significantly optimize operations.

Final Word

Automotive Inventory Management system is not just about numbers and spreadsheets.

It’s about aligning various facets of a business to deliver value to customers efficiently for customer satisfaction. Embracing its golden rules can usher in profitability, reduce wastage, and ensure business sustainability.

Staying updated and continually learning in this dynamic realm is not a choice but a necessity. As the automobile industry evolves, so should our strategies, ensuring we remain at the forefront of delivering value.

Craving more insights? Stay ahead in the automotive world by subscribing to our newsletter. From the latest trends to actionable tips, we’ve got you covered.

Don’t miss our FREE e-book on Automotive Inventory Management!